Copper alloys

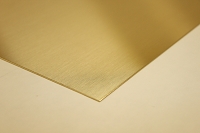

Brass

Features of brass

Brass is a copper and zinc alloy and usually consists of over 20% zinc. Brass has been used for a long time as a strong, ductile and workable alloy and has been used as a substitute for gold since it has a similar golden color shine. In Japan it has been widely used for Buddhist equipment and many brass instruments are made from it. The 5-yen coin is also made from brass. It has the following names depending on the proportion of zinc present.

Red brass: From 5% but less than 20% zinc

70-30 brass: 30% zinc

60-40 brass: 40% zinc

There are many other varieties of brass including free-cutting brass, with an addition of lead to increase its machinability, and naval brass, with additional tin to increase its resistance to damage from seawater.

Varieties of brass sheets and strips

| Varieties of Brass | |||

| Name |

JIS |

Main components |

Usage |

Brass |

C2600 |

Cu-Zn(30) |

Automobile radiators, cartridges, springs |

| C2680 |

Cu-Zn(35) |

Automobile radiators, snap fasteners, buttons, cameras, mounting brackets, switch terminals | |

| C2720 |

Cu-Zn(37) |

Metal goods, thin ties/clamps | |

| C2801 |

Cu-Zn(40) |

Mounting bracket parts, name plates, measuring devices, switch terminals, general sheet metal | |

Reference:Nisshin Shindoh Cooperative – Shindoh products data book

Other alloys

Phosphor bronze/Phosphor bronze castings/Lead bronze castings /Aluminum bronze castings/Aluminum bronze/Beryllium copper/Chrome copper/Cadmium-free bronze

Copper alloy features

Copper is made into many alloys through combination with zinc, lead, tin, aluminum, nickel, beryllium, phosphorous, silicon and additional elements. There are also many products are made including sheets, strips, tubes, poles, and lines many methods including rolling, molding, extraction and forging (hot and cold). Copper and copper alloys are very ductile and are good at being worked on, including rolling, drawing, aperture and bending, this is the origin of copper and copper-alloy based products. Copper and copper-alloys are good for being worked on when hot, and particularly good at drawing and hot forging. They also create complicated shapes. Further, copper and copper-alloy based products are non-magnetic and so are often used in electric meters.

Varieties of copper alloys

Copper is made into many alloys through combination with zinc, lead, tin, aluminum, nickel, beryllium, phosphorous, silicon and additional elements. There are also many products are made including sheets, strips, tubes, poles, and lines many methods including rolling, molding, extraction and forging (hot and cold). Copper and copper alloys are very ductile and are good at being worked on, including rolling, drawing, aperture and bending, this is the origin of copper and copper-alloy based products. Copper and copper-alloys are good for being worked on when hot, and particularly good at drawing and hot forging. They also create complicated shapes. Further, copper and copper-alloy based products are non-magnetic and so are often used in electric meters.

Varieties of copper alloys

| Main varieties of copper and copper alloys | ||

| Variety |

Alloy type |

Alloy name |

| Pure copper |

Cu |

Oxygen-free, Tough-pitch, Deoxidized-copper |

| High copper alloy | Cu-Be-Co alloys | Beryllium copper |

| Cu-Cr alloys | Chrome copper | |

| Brass | Cu-Zn alloys | Red brass, 7/3 brass, 6/4 brass, 65/35 brass |

| Cu-Zn-Pb alloys | Free-cutting brass | |

| Cu-Zn-Sn alloys | Naval brass, Admiralty brass | |

| Cu-Zn-Al alloys | Aluminum brass | |

| Cu-Zn-Mn-Al-Fe alloys | High tension brass | |

| Bronze | Cu-Sn alloys | Tin bronze |

| Cu-Sn-P alloys | Phosphor bronze, free-cutting phosphor bronze | |

| Special Bronze | Cu-Al-Fe-Mn-Ni alloys | Aluminum bronze |

| Cu-Si alloys | Silicon bronze | |

| Copper-Nickel Compounds | Cu-Ni alloys | Nickel, Cupronickel |

| Cu-Ni-Zn alloys | Nickel silver, free-cutting nickel silver | |

Reference:Nisshin Shindoh Cooperative – Shindoh products data book

HOME

HOME

Preceding page

Preceding page